The main characteristics of IONOMR cationic membrane catalyst PP1-HNN8-00 are:

High conductivity adhesives and coating materials

High concentration of functional groups

Chemical and oxidative stability

IONOMR Cationic Membrane Catalyst PP1-HNN8-00 Product Description:

PEMION+ ™ - PP1-HNN8-00 ionomer can be used as both a coating and an adhesive. The ink formula can be prepared for use in fuel cell catalyst layers. Usually, the ionomer is mixed with a suitable alcohol, then stirred and dripped with an appropriate amount of catalyst powder and water.

Typical applications include metal air, nickel metal hydride, and solid-state battery chemistry. This highly conductive adhesive material has an affinity for negatively charged electrode components. It can be processed in low boiling solvents, used as an alkaline/acidic stable electrode coating or adhesive, and is highly customizable to optimize electrochemical performance, application scale, and manufacturing methods.

The role of ion exchange polymers in membrane electrode components of hydroelectric electrolysis tanks and fuel cells

Membrane electrode assemblies (MEAs) are considered the core of hydroelectric electrolysis tanks and fuel cells. It consists of a gas diffusion layer (or porous transport layer), a catalyst layer (CLs), and an ion exchange membrane. MEA contains sites where significant electrochemical reactions occur. They are also responsible for the quality transfer process, including transferring reactants to and from the equipment, as well as conducting electrons from the electrodes to the external circuits of the electrolysis tank and fuel cell. The performance of hydroelectric electrolysis tanks and fuel cells is greatly influenced by the GDL, CL, and membrane characteristics that make up MEAs. The electrode should have high conductivity and porosity, while CL should exhibit high catalytic activity. Ideally, MEA possesses all of these characteristics while being affordable. Especially for polymer electrolyte membrane water electrolysis cells and fuel cells, cost has always been a problem, as high acidic operating conditions require the use of expensive platinum group metal catalysts, usually Pt/C.

Balancing cost-effectiveness and device performance requires optimizing membrane electrode manufacturing. MEA is typically produced through two main technologies. Firstly, the gas diffusion electrode (GDE) method involves depositing a catalyst layer on GDL. Secondly, in catalyst coated membrane (CCM) technology, the catalyst is directly coated on the ion exchange membrane through electrostatic spraying, ultrasonic coating, sticker transfer printing, and screen printing. The CCM method produces membrane electrodes with lower interface resistance due to the reduction of reactant diffusion paths and the expansion of contact area. It should be noted that due to the high aggregation of catalyst particles and solvent evaporation used in ink formulations, direct deposition of the catalyst on the membrane may lead to the formation of cracks in the CL.

In order to improve the utilization rate of the catalyst, ion exchange polymers or ionomers are added to the catalyst ink formula. Catalyst ink formulations typically consist of catalysts, solvents, and ion exchange polymers or ionomers. The electrochemical performance, coating characteristics, and coating stability of CL highly depend on the interaction of these three main components. Ion exchange polymers adsorb onto catalyst particles in CL. This adsorption increases the surface charge of catalyst particle aggregates. Due to the dominance of electrostatic repulsion between catalyst particles in van der Waals forces, the trend of agglomeration formation decreases. Most importantly, ion exchange polymer particles increase steric hindrance, causing CL particles to move away from each other. In addition to improving the utilization of catalysts, ion exchange polymers can also improve charge (anion or proton) conduction as they serve as extended charge conductors for the main body of ion exchange membranes. Ions are also used as binders for catalyst particles, ensuring the existence of available reactant transfer and conductive pathways. Finally, ion exchange polymers act as hydrophilic agents to maintain optimal moisture content to ensure sufficient membrane moisture.

Compatibility between solvents and ion exchange polymers

The way in which ionomers interact with solvents and catalysts is a key factor in determining dispersion stability and ink rheological properties. Pemion ® The dissolution of ionomers is usually achieved by stirring and mild heating (e.g. 600-60 rpm at 300 ° C) in a selected solvent for 24-72 hours, depending on the container size, concentration, and amount of dissolved ionomers. It is recommended to filter the polymer solution after dissolution.

| Solvent type | comment | Solubility wt% |

| methanol | Low boiling solvent for spraying and electrodes | 1% – 10% |

| Reagent alcohol (85% EtOHl/5% MeOH/5% isopropanol) | Low boiling solvent for spraying and electrodes | 1% - 10% |

| ethanol | Low boiling solvent for spraying and electrodes | 1% - 7% |

| Ethanol/isopropanol (50:50 by weight) | High boiling point solvents can cause complications | 1% - 5% |

| IPA/water (50:50 by volume) | Low boiling solvent for spraying and electrodes | 1% – 10% |

| DMSO Company | It is recommended to use high boiling solvents to achieve high boiling points. | 1% - 10% |

We sell ionomers in the form of pure polymer powders and provide customers with comprehensive processing and dissolution instructions to create our own solutions. This saves us and you the trouble of transporting flammable liquids, as well as related safety and cost considerations.

Both PEM and AEM are easily soluble in common laboratory solvents with low boiling points.

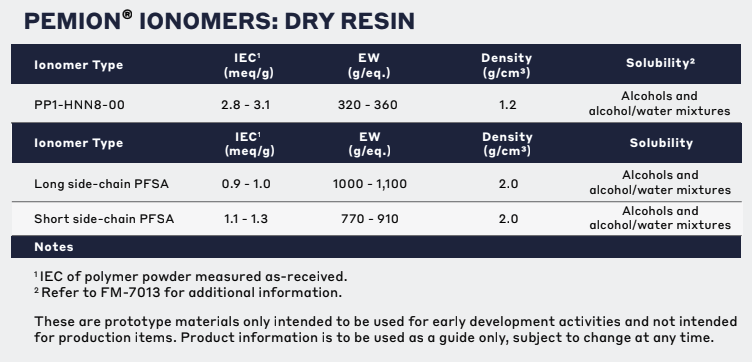

These are prototype materials used only for early development activities and not for production projects. The product information is for reference only and may be changed at any time.

微信扫码 关注我们

微信扫码 关注我们

24小时咨询热线

移动电话13820242737

Copyright © 2024 All Rights Reserved. 地址:Building B1, No. 42 Haitai Avenue, Huayuan Industrial Zone, Binhai High tech Zone, Tianjin City -404 津ICP备2022004700号-1 XML地图